ucs 66 impact test|impact test temperature requirements : manufacture If the MDMT falls below the appropriate material curve (A to D), Impact testing is mandatory. However if the item is not highly stressed there is less risk of brittle fracture, Fig UCS66.1 . Tamanho: 1012 MB. Formato: Avi. Qualidade: HDRip. Áudio: Português – Inglês. Legenda: Clique Aqui (Opção 1) ou Clique Aqui (Opção 2) ou Clique Aqui (Opção 3) Servidores: BrUpload – RockFile – Uploaded. Sinopse: Os aclamados irmãos Joel e Ethan Coen idealizam uma antologia faroeste em seis segmentos focada na fronteira americana.

{plog:ftitle_list}

6 de jul. de 2023 · Você pode gostar. 204.2K curtidas,4.8K comentários.Vídeo do TikTok de faelzin69_ff (@faelzin69_ff): "#freefire #freefirewiki #freefirebrasil #fyp #ff".som original .

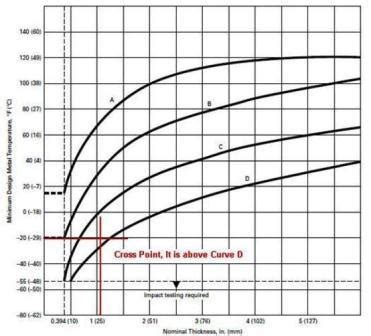

ASME Sec. VIII Div.1: UCS-66 (a) Unless exempted in UG-20 (f), Fig. UCS-66 shall be used to establish impact testing exemptions for steel listed in part UCS. Impact testing is checked for the combination of minimum design metal .

Matcha Powder moisture meter

For some cases, You might be exempted from the ASME impact test requirement in the first stage in UG-20 (f). In others, You might be exempted in UCS-66 (a) or UCS-66 (b) or UCS-68 (c). If you are not exempted, you must .If the MDMT falls below the appropriate material curve (A to D), Impact testing is mandatory. However if the item is not highly stressed there is less risk of brittle fracture, Fig UCS66.1 . Considering a different case, with carbon steel (ASME SA-516 Gr.70 for plates and ASME SA-765 Gr.II for forgings), in accordange to Fig.UG-84.1M, SA-765 has the minimum impact test reuired at -46°C, but in .

ucs 66 testing requirements

In some cases, you might be exempted from the ASME impact test requirement in the first stage of UG-20 (f). In others, you may be exempted from UCS-66(a) or UCS-66(b) or UCS-68(c). If you are not exempted, you . 1. As per UG-20 (f) it is exempted from impact test. 2. As per UCS-66, obtained -5°C of MDMT from curve B, so impact test required or use SA-516Gr70 normalized. In view .

This chart, which approximates ASME UCS-66 and appears here for illustrative purposes only, shows four temperature functions for impact testing. If an alloy is listed as belonging to Curve C, its thickness is 3.5 in., .4.3 UCS-66 (c) and Figure UCS-66: SA-105 Flange Materials The 2019 edition of ASME VIII-1 introduced more stringent requirements for impact test exemption of SA-105 flange materials.Impact Testing is indispensable in the quality assurance during the construction of pressure retaining parts and vessels. This introductory course provides the basic understanding of . The results suggest that complying with UCS-66 (c) does not necessarily guarantee acceptable toughness results for flanges that were normalized and manufactured to fine grain .

ucs 66 impact testing requirements

ucs 66 impact testing

UCS-66에서는 해당 재질이 어떤 온도일 때 Impact test를 해야 하는지, 또는 하지 않고 그냥 써도 되는지 판단할 수 있는 Graph를 제공하고 있습니다. (당연히 Impact test 결과 불합격이 나오면 그 재료를 압력용기 .

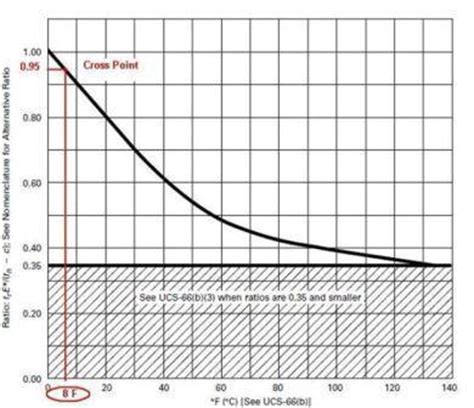

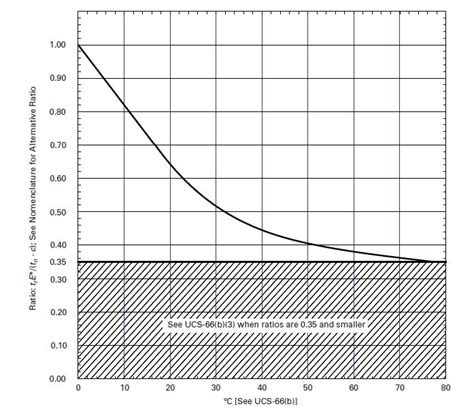

The reason is that these curves are intended for the exemption of materials from impact test which makes them meaningless for impact tested materials. 2-As per UCS-66(b)1 I can use figure UCS-66 in order to obtain an MDMT for a given C.S. and then use figure UCS-66.1 to reduce the MDMT based on the coincident ratio. If the coincident ratio is .

Considering a different case, with carbon steel (ASME SA-516 Gr.70 for plates and ASME SA-765 Gr.II for forgings), in accordange to Fig.UG-84.1M, SA-765 has the minimum impact test reuired at -46°C, but in .

As per UG-20(f) it is exempted from impact test. 2. As per UCS-66, obtained -5°C of MDMT from curve B, so impact test required or use SA-516Gr70 normalized. In view above, there is conflict between UG-20(f) and UCS-66 in some cases. This will make people confusing, which one we shall follow, UG-20(f) or UCS-66? This may virtually make a . UCS 66: I think I have answered my own question. Weld PQRs and Production test plates need to be impact tested for MDMTs below -20F for curve C & D materials unless their weld rods are prequalified by impact testimg down to -55F. For MDMTs below -55F, no more exemptions and impact testing is mandatory for PQRs and Production Weld Test Plates. Then go to Figure UCS-66(b) and in the vertical axes locate Ratio and draw a horizontal line. Then locate the cross point with the graph and draw a vertical line to cross the horizontal axis.Step 2. ASME section 8, div 1: UCS-66 Material สรุปประเด็นเอาไว้ว่า เมื่อใดก็ตามที่พวกเรา มาพิจารณาเงื่อนไข ของการหลบ impact test โดยความสามารถทางด้าน วัสดุนั้น เราจะพบว่า .

UCS-56_2020_15 - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document contains exemption curves for impact testing of steels. It lists various steel specifications and grades along with the diameter and temperature ranges where impact testing is exempted. General notes provide additional details on heat treatments, material classes and . UCS-66(c) will exempt the standard B16.5 flanges to -20° F. Exemption from impact testing to colder MDMT can be made using Fig UCS-66.1. How much colder you can go with the flanges will depend on the "coincident ratio" defined in Fig UCS-66.2, down to a -55° F per UCS-66(b)(1)(b).

Matthews, C. "Impact Testing." A Quick Guide to API 510 Certified Pressure Vessel Inspector Syllabus. Ed. Matthews, C. ASME Press, 2010. Download citation file: . 12.2 Impact exemption UCS-66. 12.3 ASME VIII section UCS-66: impact test exemption familiarization questions. Considering a different case, with carbon steel (ASME SA-516 Gr.70 for plates and ASME SA-765 Gr.II for forgings), in accordange to Fig.UG-84.1M, SA-765 has the minimum impact test reuired at -46°C, but in accordance to fig. UCS-66(3), I should consider only the minimum hub thickness.

Refer to UCS-66(d). RE: Impact Test For SA-179 stesw90 (Mechanical) (OP) 2 Sep 14 01:32. Thank you all for making me aware of ucs-66(d), . from impact testing are also permitted as a function of the material specified minimum yield strength (SMYS) for metal temperatures of −155°F (−105°C) and warmer: .UCS-56_2020_22 - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides impact test exemption curves for assessing the minimum design metal temperature for pressure vessels and piping based on material thickness. . This document provides impact test exemption curves for assessing the minimum design . Question 2: Following Question 1, according to UCS-66.Is the below vessel exempted from Impact Test qualification. Vessel Material SA-516-70 normalized (plate) Thickness 2″, Min. Yield 38 KSI, MDMT -25 °F, Coincident Ratio = 0.85 (a) YES, No need Impact Test for this product (b) NO, (c) Should to be checked further with UCS-68(c)

Rules for using materials below its MDMT without impact testing. The use of a material at a design minimum temperature colder than −29°C (−20°F) is established by para. 323.2.2 and other impact test requirements. For carbon .

impact test temperature requirements

The impact test exemption rules of UCS-66 are some of the most important and yet most misunderstood provisions of the ASME Code. Because of its importance in determining safe vessel operation, MDMT is one of just a few critical parameters stamped onto vessel nameplates. To address these complex rules COMPRESS automatically: Determines if UCS-66Associated Changes to Subparagraph UCS-66(c) for Exemption of Standard Flanges Subparagraph UCS-66(c) provides for a separate impact test exemption for certain ASME B16.5, B16.47, and long weld neck flanges, and has similarly been revised to raise the impact test exemption temperature for ferritic steel flanges to 0°F (-18°C) when they are Change in rules will provide manufacturers significant relief from production impact tests for Category-B welds that are under-stressed with safety factors currently in Figure UCS 66.1. Impact . Hence, we wish to know whether we can reduce minimum design metal temperature for tubesheet without impact testing using FIG. UCS-66.1 or not. We found that COMPRESS Software do not consider reduction in MDMT without impact testing as per FIG. UCS-66.1 for tubesheet. So we wish to know reason behind the same.

thread794-379767 To determine which curve applies to SA333-6 we have to refer to Fig. UCS-66 [Section VIII Div. 1]. Start of in Curve B since clause 2(c) states . So in reference to B31.3; SA-333-6 is exempted from impact testing if used as the base metal at -50F or higher; in conjunction with the fact that the material specification for SA .

Impact Test Exemption Curves UCS-66 of Boiler Pressure Vessel Code (BPVC) Section VIII Division-1 provides four curves for impact test exemptions rules as shown in “Fig.1”. The curves wereUCS-56_2020_10 - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides impact test exemption curves for various materials used in pressure vessel construction according to ASME BPVC.VIII.1-2019. . This document provides impact test exemption curves for various materials used in pressure vessel . 오늘은 충격시험 impact test에 관련된 내용을 다루어 볼 거예요. 전 용접 엔지니어니깐 자재 입장이 아닌 용접부 입장에서 요 충격시험을 바라볼 거예요. . ucs-66 항목으로 가면 아래와 같이 그림이 있는데 이 그림을 보고 충격시험의 여부를 파단하는 그림입니다 .

The material is exempt from impact testing per Fig UCS-66 and Note 4 thereof. Q2. PWHT is not required per UCS-56 unless in Lethal Service per U-2. Q3. WPS must be additionally impact test qualified at -55F on P No.1 Group 2 material unless the filler metal manufacturer has classified it by impact testing per the applicable SFA specification at . The basis for impact testing is stated in UCS-66. "Each component shall be evaluated for impact test requirements based on its individual material classification (SA-516-70N which is Curve D), governing thickness as defined in {1}{2}{3} below and the minimum design metal temperature (-40C/-40F)." The additional temperature reduction provided by UCS-68(c) may be applied to the provision of UCS-66(c), which allows ANSI B16.5 and B16.47 flanges and split loose flanges as specified within the Code paragraph, exemption from impact testing when the MDMT is no colder than –20 ° F. After applying the rules of UCS-66, this nozzle forging requires impact testing. Shall the maximum nominal thickness of the forging be used when determining the required impact test energy values of the nozzle forging taken from Fig. UG-84.1, regardless of the weld thickness used to attach it to the shell? Reply (1): Yes.

WEBVeja vários canais tv online e grátis. Assista pelo seu celular ou pc, canais de tv: GLOBO, RECORD, SBT e muito mais!

ucs 66 impact test|impact test temperature requirements